[ad_1]

Author: Lambert Strether of Corrente.

We have read a lot about shipping containers are “Scattered all over the place”Southern California because Congestion in the Port of Los Angeles, So I started to learn more about them (no Residential uses). It turns out that the container embodies two themes that I really like: transportation and international standards. (Most of the common sense in this article, such as it, was taken from Marc Levinson, Box: How containers make the world smaller and the world economy bigger, I bought a solid business history a few years ago, but never had time to read).

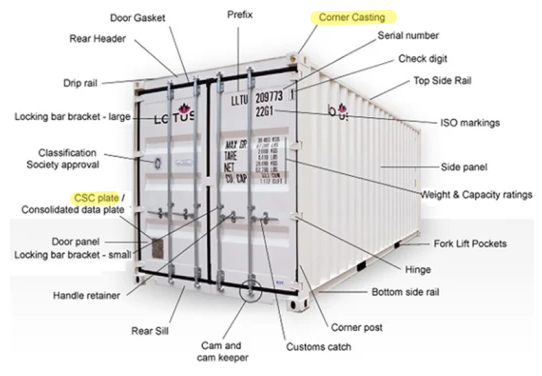

As transportation, container transportation is global.This is An image “CSC Board” (Safe Container Convention), must be attached to each international shipping container:

Among the political and business entities listed: E22G (International Organization for Standardization Size type, I believe), USA (United States of America), Electromagnetic control unit Johor, Malaysia (Evergreen Marine Corporation, manufacturer, a subsidiary of Taiwan’s famous Evergreen Group), ABS (U.S. Bureau of Shipping), as well as the metric and imperial/U.S. customary measurement fields (“KG” and “LB” respectively). There is more I don’t have time to decode.

As a product of standardization, container transportation has reached the standard. This is why companies in China can include the following images in their catalogs:

(I emphasized the CSC board above, as well as the “corner casting” we are going to introduce. The interchangeable parts are exactly the same as Eli Whitney, but are manufactured and sold globally.

Or it could be three themes, in addition to transportation and standardization.When I was young, I liked to build with building blocks. Of course, the great thing about containers lies in them Stackable:

In this article, I will study the four subject areas that show the stackability of container boxes.

- Stackable box

- Standard size box

- Lock the box connecting every corner

- The ship is designed to handle large piles of boxes.

Stackable box

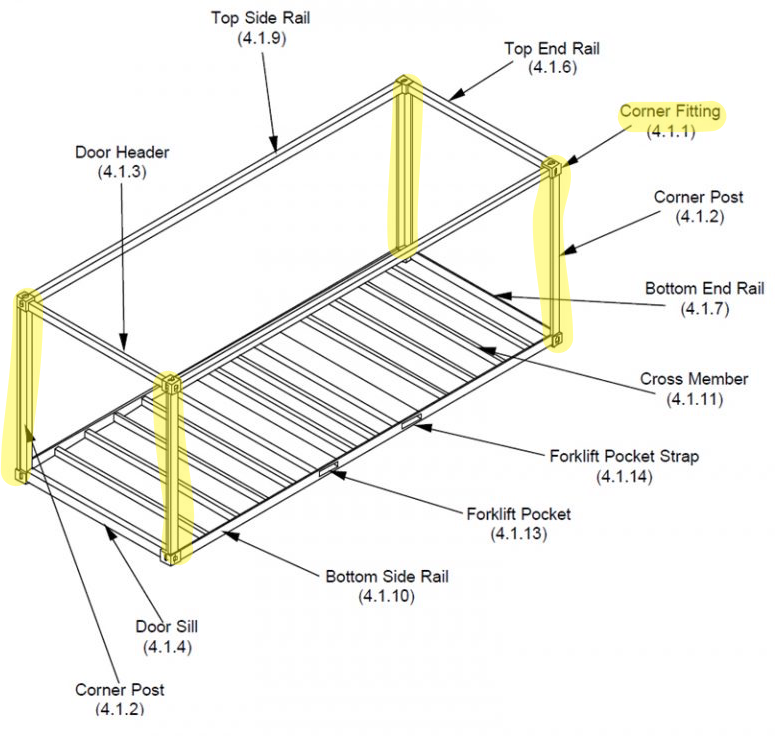

Here is one Simple graph A container box L

I highlighted the vertical “corner posts” in yellow; according to the standard, they are load-bearing elements. The sides, roof, and bottom are not. I also emphasized the “corner fittings”; these are used to connect the boxes together with “locks” (see below), and also to tie them to each other and to the boat.

Of course, if the boxes are randomly sized, it might be fun for kids to stack them, but industrial stacking requires that the box dimensions (and accessories) be standardized.

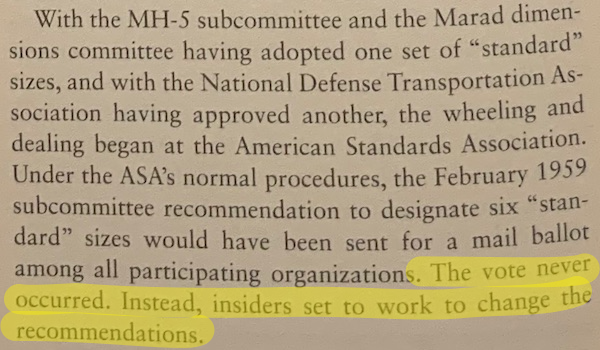

Standardized box

Standard setting-after the work of the Bolshevik committee, as we will see soon-shipping containers started with the US Maritime Administration and were transferred (or dragged) to so (American Standards Organization, now ANSI, American National Standards Institute), and then moved (or dragged) to ISO, International Organization for Standardization, Where it is today.The key ISO standards are ISO 668, “Series 1 Freight Containers-Classification, Dimensions and Ratings.” Eight pages long, excluding accessories. This is the scope of the standard:

This International Standard establishes the classification of Series 1 freight containers based on the external dimensions and specifies the relevant levels, and where appropriate, specifies the minimum internal dimensions and door opening dimensions for certain types of containers.

As an ISO standard, it normatively quotes other standards:

IS0 830, Freight Containers-Terminology; IS0 1161, Series 1 Freight Containers-Corner Fittings-Specifications; IS0 1496-1, Series 1 Freight Containers-Specifications and Testing-Part I: General Freight Containers for General Purposes; IS0 1496- 2, Series 1 Freight Containers-Specification and Testing-Part 2: Thermal Containers; IS0 6346, Freight Containers-Coding, Identification and Marking.

As an ISO standard, the text is a bit boring, but for me, it is a very beautiful thing because it facilitates a collective effort. Naturally, I hope that the process of creating this beauty is a virtual Plato seminar on engineering prowess and selfless advocacy. But in fact, it’s not. The following is a few paragraphs from Box Chapter 7 “Setting Standards”.

Committee work:

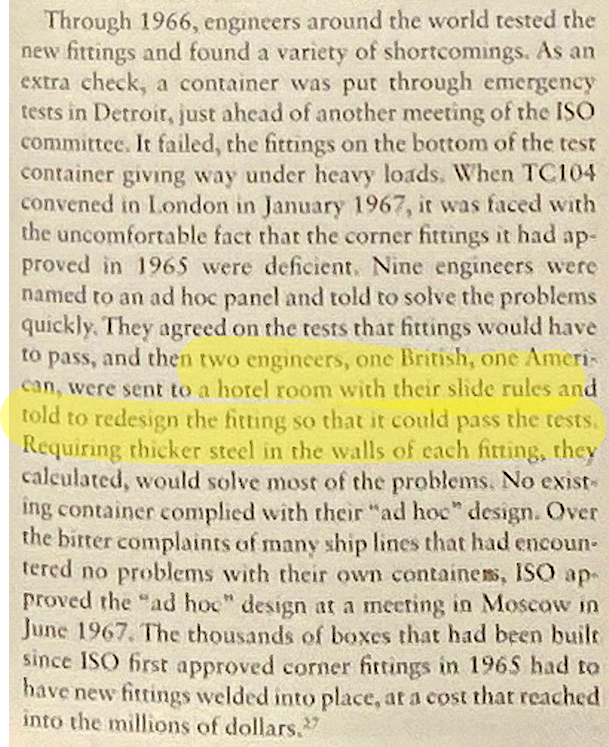

Engineering aspect:

However, the end result is:

So now we have stackable boxes with standardized (“outer”) dimensions. But what prevents the boxes in the stack from slipping out of position, turning the huge stacked carrier ship into a collapsed stack of towers? The answer is that adjacent boxes can be locked together at their corner fittings. Corner fittings and locks are also standardized.

Lock the box connecting every corner

“Corner fittings” are metal castings with holes into which locks (“twist locks”) can be inserted. (You can also insert lashing ropes or crane hooks. Truck chassis There are also corner fittings, and the truck driver locks the container on the corner fittings. ) From the manufacturer:

ISO1161 [naturally] Corner castings are large three-hole weathering steel blocks that form the corners of all ISO containers. Cast from weathering steel, usually in India or China, weighing 2.5 kg (23 lb), they are structural elements used to lift containers and connect them to any means of transportation (such as ships) used to move containers, trains or road vehicles . They are also the connection points for the interconnection of shipping containers, just like the stacks of containers on a container ship.

In order for all lifting and container transportation equipment around the world to work properly, these corner castings have holes, which have been standardized to a tolerance of only millimeters.Because of this standardization, no matter what you need to connect to your container, no matter where you are, the Domino clip is guaranteed to be compatible with your ISO shipping container

(For someone like me, he puts “Stan“In the standard, “Domino Clamps are guaranteed to be compatible with your ISO shipping container” should be accompanied by swelling music.)

This is a manufacturer video showing how the corner fitting works:

(There is a full set of container videos on YouTube. Interestingly, the comments I saw were sober and well-informed, probably because handling containers on ships, ports, trucks, and railroads is a technical profession. Some have risk.)

This is how the lock (“twist lock”) connects the containers together at the corners.From Wasir:

Mechanical locking device at the corner of the container. The traditional twist lock is manually locked and unlocked by an operating lever. Twist-lock foundation that rotates the movable part around a vertical axis to lock the device and the container to the hatch cover or another container. The reverse movement effect is unlocked. The semi-automatic twist lock is automatically locked and manually unlocked by the operating lever. The fully automatic lock is placed in the lower corner of the terminal container. The container is automatically locked after being placed on the top, and automatically unlocked when the container is lifted.

This is a manufacturer video showing how twist locks work:

(This is A link to a rougher video, Which shows that a container ship and its containers are rusty and full of salt. )

The ship is designed to handle large piles of boxes

I don’t really want to get involved in the shipbuilding industry, but I found it so attractive that I had to include it. In any case, we might as well understand how piles of boxes sail on the sea to cool the propellers in the Port of Los Angeles. Here is some information about container ship design.

First, business considerations determine speed.From Ocean Insight:

Goods transported in containers are usually of high value and high priority. For example, if the marine diesel engine of a ship built in an Indian shipyard is to be shipped from Germany, the shipment will be carried out in a container and is a high-priority shipment, because the installation of the engine in the engine room is a step in the construction process. It will determine the possibility of delays in the later stages of construction. In addition, the equipment needs to be delivered without any impact or damage. Therefore, container ships are ships with strict time limits. Their turnaround time is very short, that is, they must have the least time for loading and unloading at the port in order to be able to call the next port without delay. Because of this, container ships belong to the category of high-speed ships. In order to achieve high speeds, the resistance of the hull needs to be minimized, which is achieved by the fine hull. In other words, the buoyancy coefficient of the container ship hull is very low, between 0.6 and 0.7.

this Once given It may look like a grotesquely fat bathtub, but it costs 22.8 knots (26.2 miles per hour. A Cruise ship Sailing at a speed of 20 knots; oil tanker logging along the way At 12 or).So, if I understand the “fine form” correctly, the container ship should move in the water Like a yacht, not a bargeHowever, in the middle of the ship, we have a large box to hold a stack of boxes:

Another significant geometric feature of container ships is the high prismatic coefficient of the hull shape. In other words, the hull section of most of the length of the ship is almost rectangular. This is done to accommodate the maximum number of containers under deck.

We need to make sure that the big box (“twist box”) is not violently distorted by the ocean:

Imagine the effect of cutting a paper cup to strengthen the edges. When extrapolated to the effect of a container ship, the same effect can cause a destructive failure of the hull structure due to torsion. To prevent this, the top edges of the port and starboard sides of the container ship are reinforced with high-size webs to form a box-like structure on each frame. This is called a torque box. A torsion box extends along the entire length of the ship from the aft peak bulkhead to the front collision bulkhead.

in conclusion

I hope this adventure will provide information or at least be interesting. In reviewing the wonderful engineering and manufacturing processes that constituted the container revolution, I was shocked by some things.

First, compare container shipping with the operation of the Port of Los Angeles: it seems that costs, rents (and profits) are hindering the problem. Nothing to do with containers, ships, trains, trucks, cranes or any materials. People can hardly help imagining that productivity and production relations are in conflict to some extent.

Second, compare software engineering. Why is the wonderful system of distributing goods in a standardized way developed for goods, not for data or code?

[ad_2]

Source link