[ad_1]

Murata and other Japanese tech suppliers are reducing their reliance on China as the U.S.-China standoff deepens.

Murata, the world’s largest capacitor maker and iPhone parts supplier, said in November that it will open a new factory in Thailand in October 2023. In an interview with Nikkei Asia, Murata President Nakajima President Norio Nakajima said the new plant will eventually be expanded into the largest one in Wuxi, near Shanghai, where Murata makes multilayer ceramic capacitors for consumer electronics.

More than half of Murata’s revenue comes from Greater China, a share that is expected to decline over time as the company seeks future growth in the Indo-Pacific. This is an example of how Japanese companies are trying to deal with geopolitical risks in the U.S.-China competition.

“There is a risk of events beyond our control,” such as Washington’s imposition of a technology ban on China, Nakajima said. “We have to diversify our supply chain.” He added that major customers such as Apple are also diversifying away from China. Murata once symbolized the enduring economic ties between Asia’s two largest economies, but the U.S.-China trade rift has business leaders like Nakajima nervous.

Murata isn’t just dealing with a trade war. It is also studying long-term demographic trends.

This article comes from Nikkei Asia, a global publication with a unique Asian perspective on politics, economics, business and international affairs. Our own correspondents and external commentators from around the world share their perspectives on Asia, while our Asia300 section provides in-depth coverage of the 300 largest and fastest-growing listed companies from 11 economies outside Japan.

“The most populous country today may be China, but by 2030 it will be India, and in the future it will be Africa,” Nakajima said. “Will these economies be aligned with China or the U.S.? We don’t know. We should be able to handle both.”

Nakajima, who became Murata’s president in June 2020, is credited with transforming the Kyoto-based company from a local electronics maker into a major supplier to Apple. He was the first company leader outside the founding Murata family.

The company provides smartphone equipment, such as filters for receiving some radio signals; amplifiers for boosting transmitted signals; and duplexers for processing input and output signals simultaneously. They are used in Apple iPhone, Samsung Galaxy, and Huawei Mate smartphones, among others. Nakajima said the components are installed in smartphones in China and then shipped to end markets, with the U.S. being the most important market.

Even though they perform the same function, the components need to be designed differently to match each smartphone brand’s operating system, Nakajima said. With the trade war putting up barriers to technology transfer, each brand has developed its own designs and operating systems, which means parts suppliers must also tailor products accordingly, adding to the overall workload in the process. “It’s a tall order,” Nakajima said.

For Murata, U.S.-China decoupling is not the only supply chain challenge. Chip shortages have hampered production by Japanese automakers, slowing demand for electronic components, he said.

Nakajima said Murata itself had difficulty supplying products such as power tool batteries and automotive WiFi modules due to shortages of power management ICs and transceiver ICs. He expects chip shortages to ease this year.

Murata isn’t the only Japanese tech company tweaking its supply chain amid geopolitical uncertainty.

Top Japanese chipmaker Renesas is concerned that it could be banned from supplying China, a market that accounts for 22 percent of its sales, because of the U.S.-China trade war.

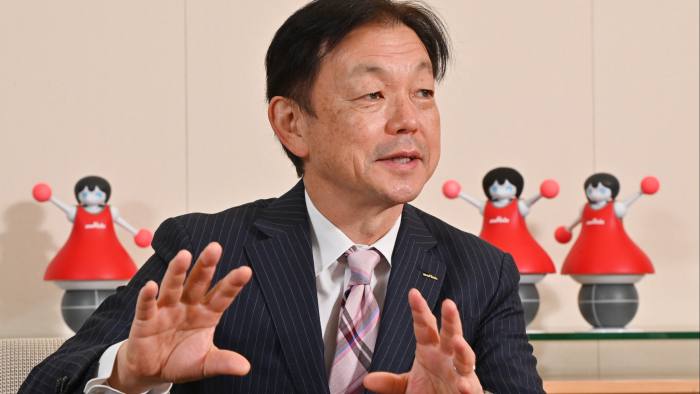

Murata’s Nakajima sees the need to diversify away from China because of “the possibility of events beyond our control” such as Washington’s tech ban © Atsushi Ooka

Renesas Electronics’ main business in the United States is the manufacture of analog semiconductors that convert analog signals such as sound, image, motion, and temperature into digital signals. The United States is the global center for analog semiconductor production, led by Texas Instruments and Analog Devices.

In 2021, Renesas acquired UK-based Dialog Semiconductor for $6 billion in an attempt to diversify its technology base into Europe, potentially using European technology to supply chips to China.

Renesas Electronics CEO Hidetoshi Shibata emphasized the importance of acquiring talent and technology in the US and Europe. At an industry event hosted by global industry association SEMI in December, he explained how the Tokyo-based company was created through the 2010 merger of the semiconductor businesses of Hitachi, Mitsubishi Electric and NEC, through the past five years in the US A series of acquisitions also filled its talent gap in Europe through the acquisition of Dialog.

“Talent is the most important thing,” Shibata said.

Tokyo Electron, one of the world’s largest chip equipment makers, is another company in a race to diversify geographically.

Tokyo Electron CEO Toshiki Kawai attended the SEMI event to describe his company’s strategy to strengthen its leadership through close ties with top European companies amid growing challenges from Chinese chip equipment makers. He highlighted the recently announced collaboration with Belgian research institute Imec and leading lithography machine manufacturer Dutch company ASML to develop cutting-edge chip manufacturing equipment.

“In order to develop next-generation devices, we will promote cooperation with customers around the world,” Kawai said.

Like the US, China and Japan, Europe is now trying to increase local chip production to minimise the risk of supply disruptions amid tensions between mainland China and Taiwan.

Europe used to be a big chip producing area. It now accounts for only 10% of global production, as companies such as STMicroelectronics and Infineon subcontract production to foundries such as TSMC.

Europe wants to increase its global share to at least 20% by 2030.

Chip equipment makers could benefit from these countries’ moves to localize their semiconductor supply, raising questions about where they should set up shop. Tokyo Electron’s production takes place almost exclusively in Japan, although more than 80 percent of its sales come from overseas.

“Our competitors are moving production overseas to be closer to their customers,” said a Tokyo Electron official. This will make it easier for them to serve customers rather than from supply chains all over the world. “We will have to think harder about whether we should produce in Japan or overseas,” the official said.

a version of this article First published by Nikkei Asia on January 10, 2022. ©2022 Nikkei Inc. All Rights Reserved

Related Stories

[ad_2]

Source link