[ad_1]

Sometime in the spring of 2020, Sam O’Leary’s phone started ringing.

The caller is a manager from the automotive and aerospace industries. They were all enlisting the help of his German-based industrial 3D printing business, SLM, to produce vital parts that have suddenly become scarce as the Covid-19 pandemic disrupted international shipping.

“I didn’t leave the office for a day,” said O’Leary, who began showing clients the company’s purpose-built machines over video calls. His client’s concerns were consistent, saying: “I have a big problem, I need to de-risk, I need to relocate.”

To date, SLM’s customers have used its technology for niche applications such as the production of gooseneck brackets for aircraft and brake calipers for high-performance vehicles.

But despite the increased cost and complexity of 3D printing metal parts, they turned to the technology to make more mundane parts — like the hinges that hold common car seats in place.

As a result, the Lübeck-based company’s revenue rose by more than a quarter in 2020, despite stagnating orders for many other industrial players.

Sales are expected to see similar growth in 2021. O’Leary expects SLM sales to grow 40% in 2022.

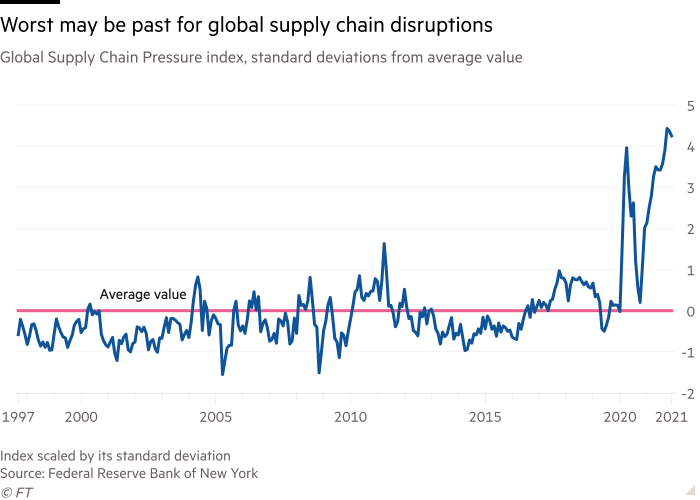

Global supply disruptions Chains over the past few years — including the temporary blockage of the Suez Canal, floods and fires in Texas and Japan, and ongoing semiconductor production bottlenecks — have led to equally optimistic forecasts for the rest of the so-called “additive manufacturing” sector.

last year, A study by Lux Research The 3D printed parts market is estimated to be worth $12 billion by 2020 and will grow to over $50 billion by the end of the century.

Governments around the world are looking to address how and where components are made. In Germany, a recent chronic shortage of semiconductors has resulted in the production of a few million fewer cars than customers want to order. As such, it is one of many countries that have pledged to support the “return” of manufacturing of critical components to protect their economies.

But despite this enthusiasm, there is growing evidence that businesses like SLM serve a small market.

An EY survey of European companies during the lockdown in early spring 2020 found that more than four-fifths Considering bringing their supply chain closer to home.However, when the same survey was conducted last April, this view was Only 20% of respondents.

Likewise, only 15% of multinational companies surveyed by the German Chamber of Commerce and Industry (DIHK) said they would relocate production.

Their stance was echoed by sporting goods group Adidas. Just five years ago, the company launched a program to build factories in Germany and the United States to produce custom sneakers for nearby customers using local materials and advanced manufacturing techniques, such as 3D printing.

It is an illusion to think that an industry that has been in Asia for over 30 years can be moved to a very mature industry, to certain regions

it had to almost give up This plan came at the beginning of the Covid-19 pandemic. But boss Kasper Rorsted insisted he had not changed his attitude towards manufacturing after supply chain disruptions cut Adidas’ revenue growth by around 600 million euros in the three months to the end of September 2021. Backflow view.

“We have about 800,000 people deployed in our [suppliers’] factories,” he said in November. “It’s an illusion to believe that you can move an industry that has been in Asia for more than 30 years into a very complex industry, to certain regions. “

Rorsted added that even though this is theoretically possible, the need to source raw materials from around the world to produce these parts makes the prospect of reflow a “complete illusion”.

“You can’t even find anyone [that would need to do the work currently being done in Asia],” He said.

Nor are German economists convinced.

“If the EU were to even partially decouple from international supply networks, this would significantly reduce living standards within the EU and its trading partners, so every effort should be made to avoid it,” warned Alexander Sankamp. He is one of the authors of a study by the Kiel Institute for the World Economy, which shows that regionalized production will cost Europe hundreds of billions of euros.

According to insurance group Munich Re, the recent floods in Germany cost the country 40 billion euros in damages, further proof that “shocks can also hit our doorsteps,” Sandkamp added.

Demand is definitely increasing. .. but there is also the reality that this is a regulated technology and change that will take time

Even SLM’s O’Leary was quick to warn against his firm’s optimistic forecast.

“We mostly work with regulated industries,” he said. “So, if you’re in the aerospace supply chain . . . you don’t just buy a 3D printer and say, ‘Okay, okay, I’ve decided to leave my supplier [they are] In the world, I’ll do this internally’.

He added that a recent development programme with a major UK aero-engine manufacturer took two years to get up and running, as it would take time to install the necessary machinery on site and obtain the necessary approvals from the UK Civil Aviation Authority.

“Demand is definitely increasing,” O’Leary said. “But there is also the reality that this is a regulated technology and change that will take time.”

Additional reporting by Olaf Stobeck

[ad_2]

Source link