[ad_1]

As the global supply chain crisis hit Malcolm Kerr’s business, the cost of its key raw materials has seen an unprecedented surge.

Kerr’s company in Tuscany has added luster to the superyacht-and his most important ingredient-the cost of paint has soared.

“The problem of raw materials is likely to be the last nail in many people’s coffins,” said Cole, whose business Storm Yachts is under severe pressure. “At some point, because we can’t continue to reduce prices and increase costs, certain things will change. This has no good results.”

Paint is one of the most widely used industrial products, and the supply chain is complex, and it is an ideal raw material to illustrate the depth of the crisis.

Almost every industry needs paint-from aerospace, construction and electronics to automobiles. It is also used in applications in the marine, medical, military, pharmaceutical, semiconductor and textile industries.

The tightening of global supply chains has caused soaring costs for everything from paint and steel to energy and grain prices.

In the energy sector, the crisis forced the company to close down due to soaring prices hitting producers.

Consumers bear the brunt of the $164 billion coatings market dominated by global manufacturers such as Sherwin-Williams, PPG and Akzo Nobel, as manufacturers raise prices to protect profits as costs rise.

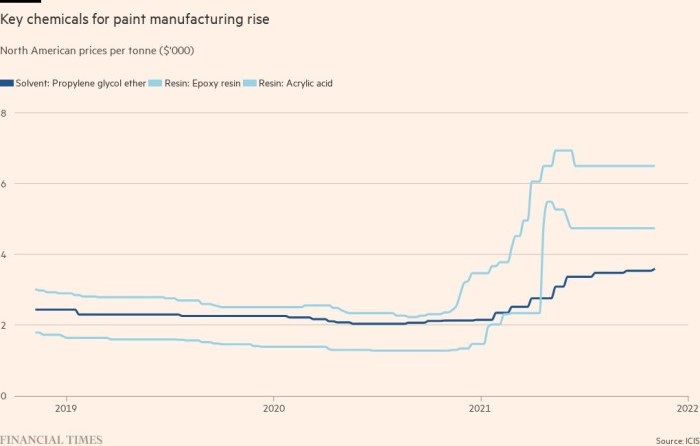

Prices have also soared due to the DIY boom during the lockdown and supply shortages after extreme weather events Texas with Louisiana State Production is carried out in a petrochemical plant that produces paint raw materials.

China’s transportation bottlenecks, shortage of truck drivers and power shortages have exacerbated supply disruptions.

Akzo Nobel, Europe’s largest paint manufacturer, plans to continue to raise prices next year, on the basis of a 15% increase in 2021, as costs (including the cost of tin cans containing this liquid) have risen sharply.

Michael McGarry, chief executive of Pittsburgh-based PPG, stated that costs have risen by 25% every year-“three times the peak inflation of any coating material in recent history.”

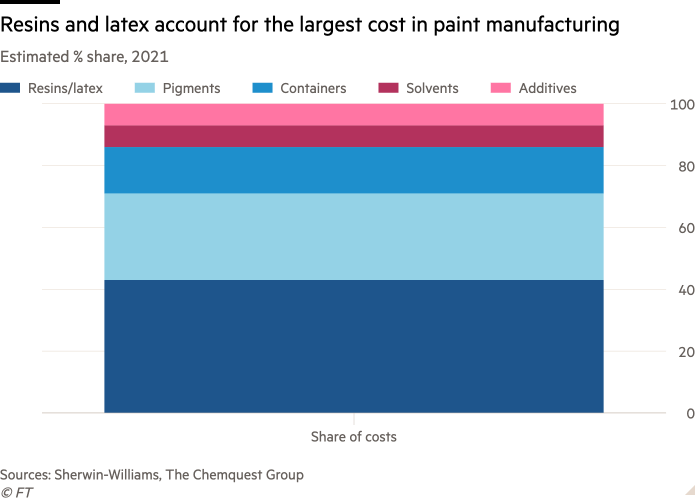

Due to the diversity of formulations, the cost pressure of paint manufacturers has become greater, requiring thousands of raw materials, most of which can be traced back to oil, natural gas or titanium dioxide-the prices of these commodities have risen.

Paint additives have been hit hardest. Dan Kersting, director of global business development for additives at Frankfurt-based resin supplier Allnex, says they are the vital “salt and pepper” ingredients in paint.

This has prompted paint companies to consider diversifying the purchase of additives, although the quantities used are small. So far, they have been fully supplied by a few large suppliers such as BYK, Dow and BASF.

“Once the supply chain is squeezed, additives will be hit hardest first,” Kersting said. “It used to be price, price, availability. Now it’s’Where are you, where is your backup. We will approve your product, but we want to approve it from two sites.'”

As manufacturers try to reduce the risk of over-reliance on raw materials in remote parts of the world, these pressures are expected to force the paint supply chain to become more regional.

Katarina Lindstroem, chief operating officer of Danish coatings group Hempel, said: “We don’t want to put rare materials on board with long delivery times.”

Jeremy Pafford, head of the consulting firm ICIS North America, said: “The further the chain goes, the greater the risk, the more you need to move to the correct step. In the past two years, multiple steps have been cut. From a logistical point of view, it is more difficult to call for reinforcements.

“You will be surprised to see how many people have so few diversified suppliers.”

However, for Kerr’s marine coatings business, the pressure is even greater, because the paint price of the superyacht has been agreed with the shipyard two years in advance, so there is almost no room to quickly pass on the cost.

Other industries, such as the insurance industry, have also been hit as they are suffering from rising raw material costs to repaint cars involved in crashes. According to David Creswell, chairman of the trade organization of the Auto Body Professional Club, paint accounts for almost a quarter of the cost of car repairs.

Martin Milliner, head of claims at LV= General Insurance, one of the UK’s largest car insurance companies, said, “When we repair so many cars, the increase in paint prices is a problem for us.”

It usually repairs 110,000 cars a year, but due to a shortage of semiconductors, a shortage of new cars has increased this number. This has led to more cars being repaired after the accident, forcing prices to rise further.

“We are using more paint to repair more cars,” Milina said, adding that due to cost pressures, premiums may start to rise next year.

For the coatings industry, the semiconductor tightening also means fewer cars need to be painted due to reduced production.

Some executives dismissed the coatings market’s concerns, saying that the price increase of the product would help expand profit margins without affecting consumer demand.

“You don’t remember how much you paid for paint last year,” said Maarten de Vries, Akzo Nobel’s chief financial officer.

However, other executives close to customers worry that demand will weaken.

Lick, an online paint retailer, has kept prices unchanged at the expense of profits after accelerating one-year cost growth in the past four months.

“It is very important in a period of inflation and customers being squeezed to keep our prices flat,” said CEO Lucas London. “We must have seen a strong sense of price.”

[ad_2]

Source link